FABRICATION OF WATER FILTER FROM RICE HUSK WASTE PRODUCT VIA COLD ISOSTATIC PRESSING (CIP) METHOD

Abstract

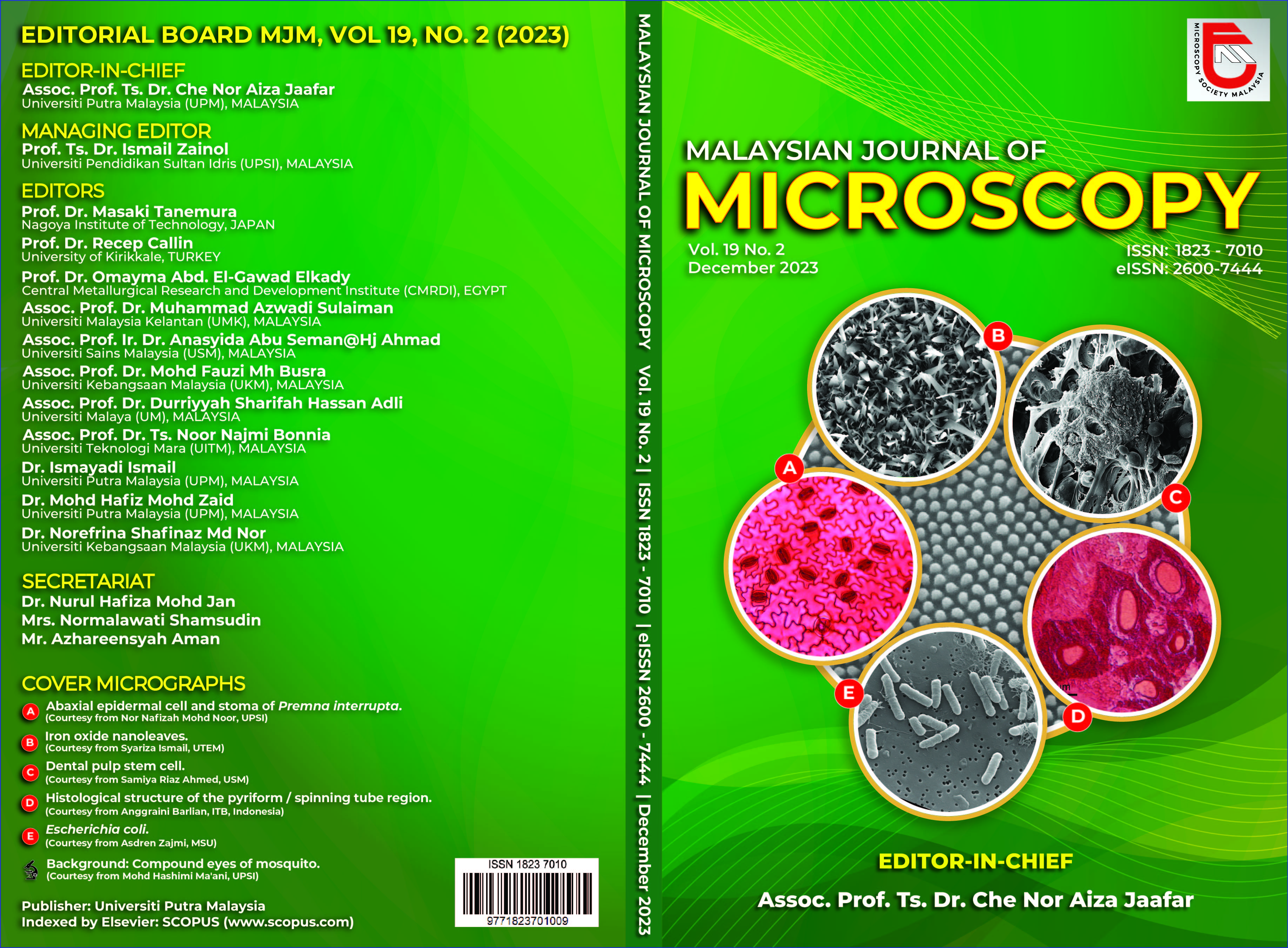

Many researchers are interested in exploring the practical ways to expand the usage of RH waste. The objective of fabricating the silica water filter is to remove contaminants from the well water. The fabrication process involves burning Rice Husk (RH) waste at 550 °C, which produces black RH ash that contains a generous amount of amorphous silica. The silica water filter was fabricated with varying the compositions of silica rice husks which were 78 wt.%, 84 wt.%, and 88 wt.%. Porcelain and PVA has been added in the mixture and acting as a binder. The mixture of amorphous silica and binders have been used to fabricate the silica water filter by using Cold Isostatic Pressing (CIP) method. The CIP pressure used was 8 kPa and the mold used was rubber plastic. After compaction using the CIP method, the samples were sintered at a temperature of 1200 °C. The results obtained from the Scanning Electron Microscope (SEM) analysis provide visual insights into the pore structure of the sample under examination. Apparent porosity, and bulk density were recorded for each sample. The results obtained for the composition of 78 wt.%, 84 wt.% and 88 wt.% for the bulk density are 0.43861 g/cm3,0.3729 g/cm3 and 0.35143 g/cm3, respectively. The result for apparent porosity for every composition of 78 wt.%, 84 wt.% and 88 wt.% are 54%, 60% and 68%, respectively. The results indicate that the 78 wt.% silica composition produces the best silica water filter. Overall, our findings demonstrate a promising approach for repurposing RH waste and producing a sustainable water filtration solution.